How Is Lead Abatement Different From RRP for Commercial Properties?

Many people believe, or hear, that RRP is a viable solution for dealing with lead paint. Unfortunately, a renovation or paint job isn't enough for dealing with lead paint. RRP doesn't eliminate or even reduce lead. Only true lead abatement can do that.

What Is RRP? How Does It Deal With Lead Paint?

RRP stands for Renovation, Repair, and Painting. It doesn't refer to a single job that encompasses all three of those things. Rather, RRP represents a rule for mitigating the effects of lead paint while doing any one of the referenced activities.

The reason RRP exists as a rule comes from the fact these activities can increase lead exposure. Any renovation, repair or paint job runs the risk of disturbing existing lead paint. When that happens, lead paint dust and chips can come loose and contaminate the area.

When someone hires a contractor to do a renovation, it's typically not to deal with lead specifically. If your facility is old enough to possibly have lead paint, the RRP contractors you hire must have EPA-approved training before they can do any work.

In addition, a contractor performing RRP work cannot perform any kind of lead abatement unless they're licensed to do so. As an example, you can hire a contractor to do a renovation. The contractor may say they need to remove the lead paint to do the job properly.

If that contractor doesn't have licensing and certification for lead abatement, then you should not hire them. Only an EPA-certified lead removal company can do that for you safely, properly and legally.

How Is RRP Different From Lead Abatement?

While lead abatement can sometimes resemble RRP work, it's a completely different type of procedure. Lead abatement concerns itself with the permanent removal of lead or extreme mitigation of the effect lead can have.

Lead abatement falls under a broader category of lead-based paint activities. These activities include lead-based paint inspections, risk assessments, lead testing and abatement. There are four main types of lead abatement.

Lead paint removal. Removal can involve various methods to remove the lead paint without releasing it into the environment in the form of dust or chips. ·

Lead paint encapsulation. Encapsulating lead paint requires the application of a special, watertight coating over the offending paint. ·

Lead paint enclosure. Enclosures, such as additional walls, materials or other physical barriers, can go up and block the lead paint. ·

Replacement. This option involves completely removing the part of the structure that has lead paint and replacing it.

Many of these abatement processes can occur in unison. It depends on your commercial property, budget and the results of your inspection or assessment.

As you can see, many of these abatement methods look like RRP jobs. In some cases, they are. Just know the focus of abatement is to deal with the lead paint. Everything else is secondary to that. By contrast, RRP work may never even take lead into consideration.

For many commercial buildings, lead abatement can become a legal requirement. This requirement can prompt many property owners to group lead abatement in with some overall RRP work. That's fine as long as you understand there are requirements for working with or around lead paint all contractors must adhere to.

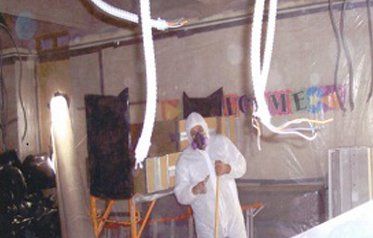

RRP contractors require additional training if they want to work around lead paint. Lead abatement contractors require even more training. They also have stringent rules and procedures they must follow when they go about the abatement process.

At Abate and Insulate, LLC, we have the experience, training and EPA-certification to perform lead paint removal in the state of South Carolina. If you have questions about lead removal from your building, or want to know more about the lead removal process, contact ustoday.